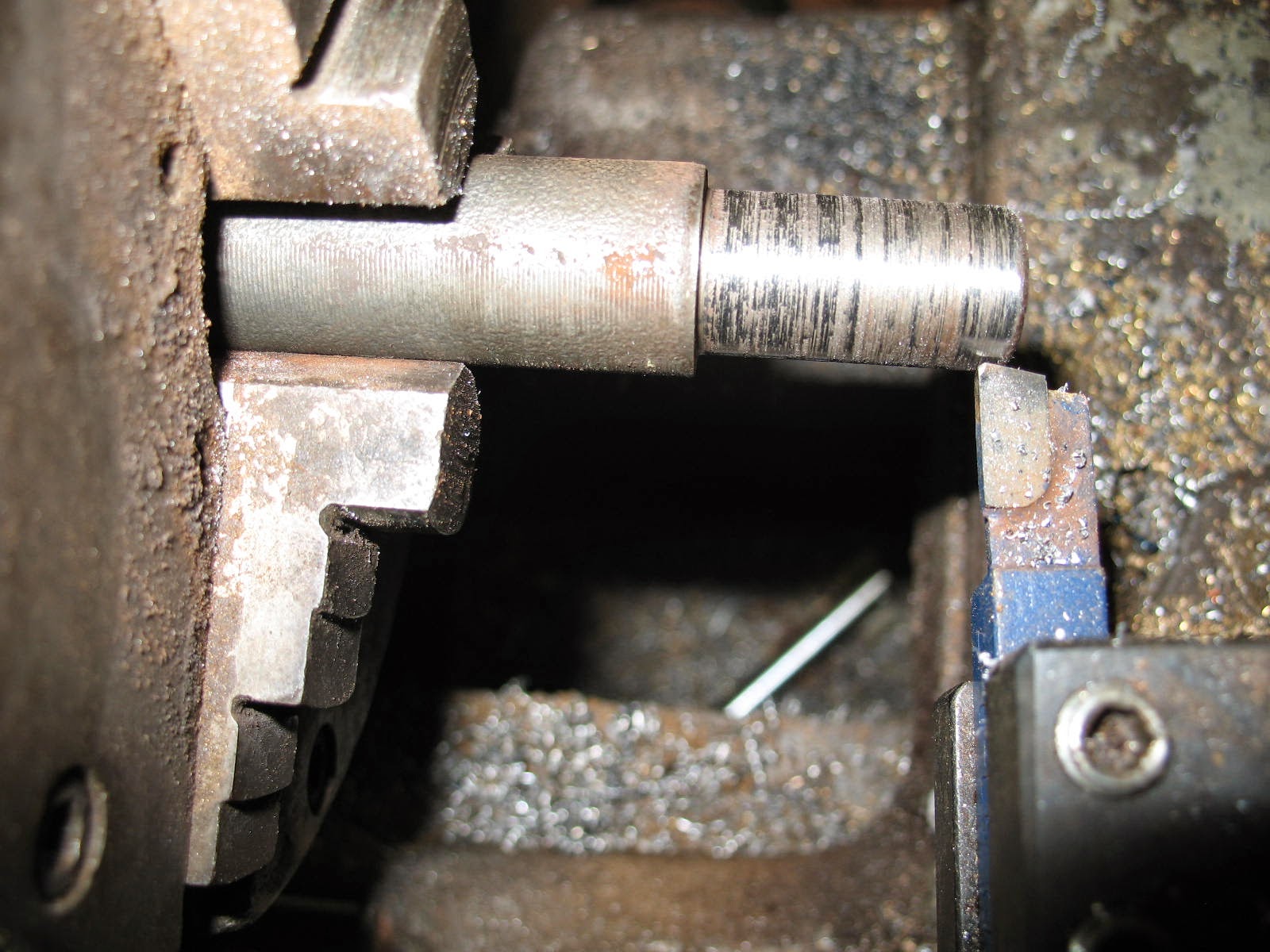

After finding out yesterday we needed shims under the carrier bearings to pre load the assembly, I removed the axle housings and took out the carrier assembly and pulled the bearings off of it. I had two .005 shims but thought it would not be enough. I had a roll of .003 shim stock so I decided to make some shims. I made four .003 so each side would get a total of .011 in shims.

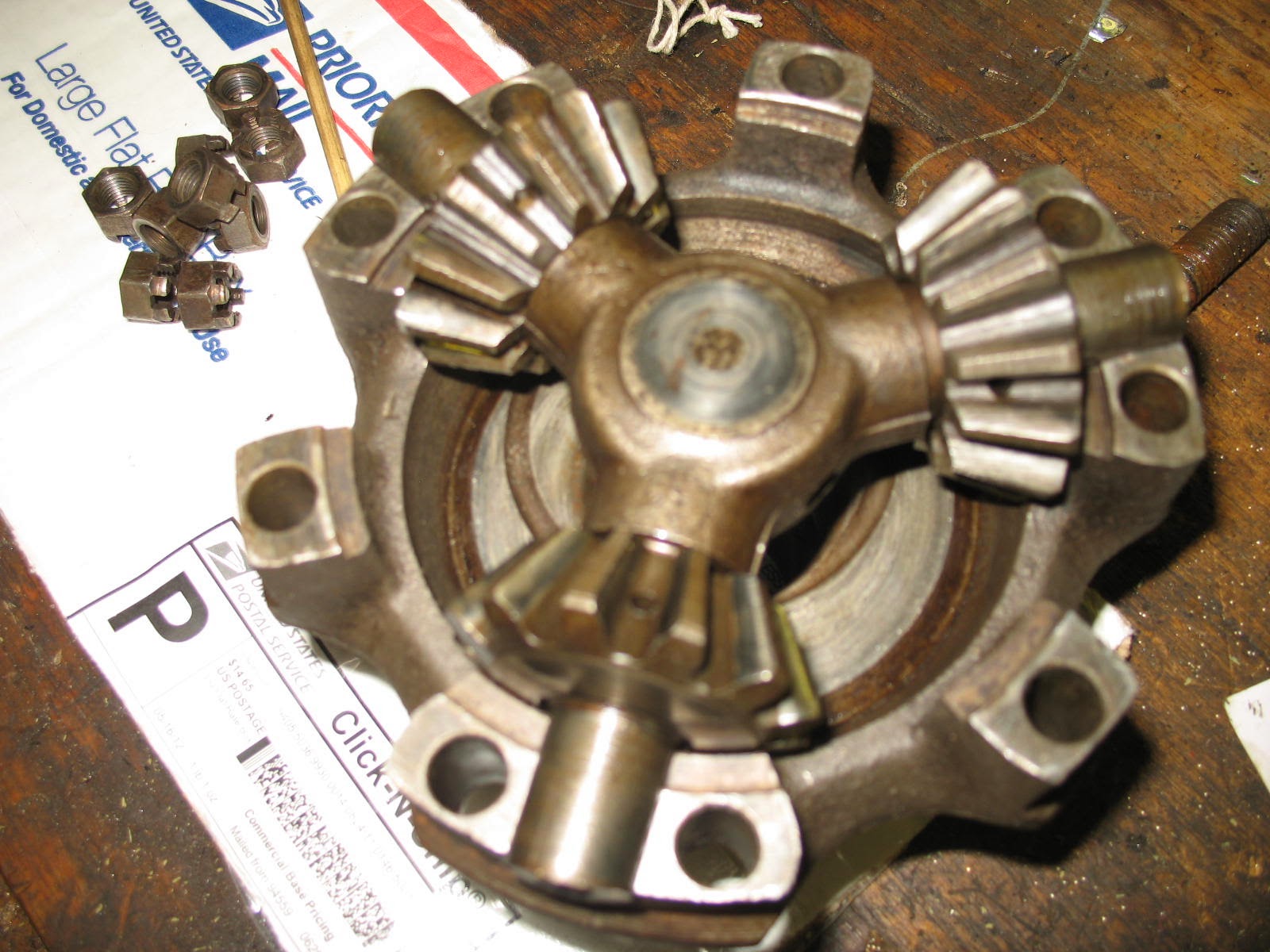

Installed shims on carrier housing and re installed the bearings.

Then re installed the carrier and axle housings and torqued to specs. This time the carrier locked up as it should have.

Next I checked the housing gaskets for thickness and marked them.

Now I can dis-assemble the rear end and use the different thickness gaskets to get my backlash correct on the gears. Hopefully I won't have to repeat these steps with the pinion bearings but it might have to happen to get the gears meshed correctly. Later, Steve