This week I decided to take off the bottom of the bad drivers side quarter panel and make a new one.

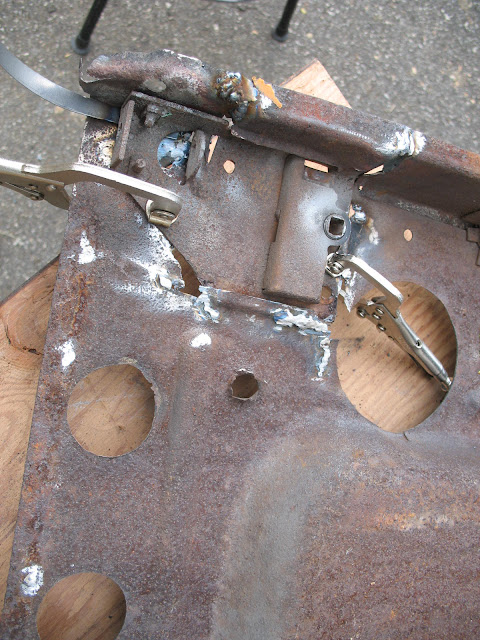

The first picture shows the old section cut loose from the quarter. As you can see it was rotten and full of holes and bondo.

The second and third picture show the new panel cut and being fit into place for welding. I cut the fingers on the patch to allow the panel to curve and to fasten and space it to the sub rails. The contour on the edge did not match up to the original quarter so I had to hammer and dolly it to make it match.

The fourth picture show the patch welded in and ready for final metal smoothing.

The fifth picture is a view of the patch from inside the quarter. Tomorrow I will finish welding up all the holes and cracks on this quarter and get it ready to prime.